Strong partnership makes digitalization easy:

We’re committed to making plant digitalization easy for you. From design through implementation to optimization and further development of your digitization solution, we work together with you every step of the way. Your team also receives comprehensive training and full access to our EVORIS services. Expert support, regular updates and new functional developments steadily enhance your EVORIS experience.

AI- and development competence for your smart production:

We combine artificial intelligence (AI), development know-how and wood-based panel market expertise and bring together the key success factors in EVORIS:

- Complete and agile in-house development of the EVORIS apps and AI algorithms

- Expertise of the wood-based panel market and understanding of our customers’ requirements and challenges

- Latest AI know-how through development cooperation with Fraunhofer IOSB, KIT – wbk

Take your wood-based panel production further with EVORIS

EVORIS Platform

The EVORIS Platform, which includes the iba-system and EVORIS Start Center, lays the foundation for the comprehensive and sustainable digitalization of your wood-based panel plant. The iba-system, a proven standard system in the industry, collects all plant data in a central database on edge. Each EVORIS app then processes these data according to its function. In the modern EVORIS Start Center you can intuitively access and operate all apps. You get exactly the information you need to gain the best insights for controlling your production plant.

BENEFITS

- Digitalize your plant comprehensively and efficiently

- Use a manufacturer-independent system

- Collect and process data at a central point

- Operate EVORIS solutions easily and intuitively

EVORIS apps

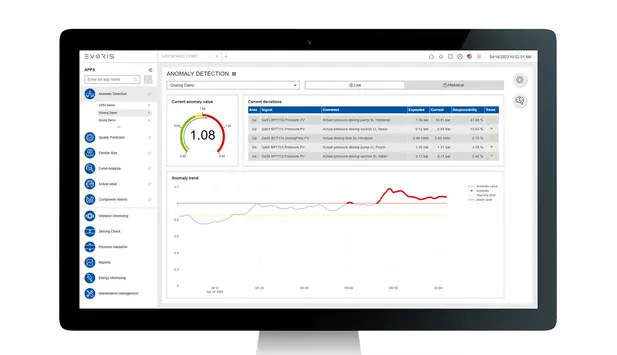

Anomaly Detection

Anomaly Detection

With the self-learning Anomaly Detection app you see exactly when and where deviations occur in your production process. The app is based on artificial intelligence. It informs you at an early stage in the event of an anomaly and gives you insights into signals causing the anomaly. Operating multiple anomaly models simultaneously allows you to quickly conduct very specific root cause analysis and to intervene, if necessary. You can better prepare for emerging problems to solve them faster. In this way you can prevent downtime and produce wood-based panels of ideal quality.

BENEFITS

- Identify errors and wear at an early stage

- Be better prepared for problem solving

- Achieve stable and optimized board quality

- Reduce rejects

- Reduce downtime and avoid an abrupt production stop

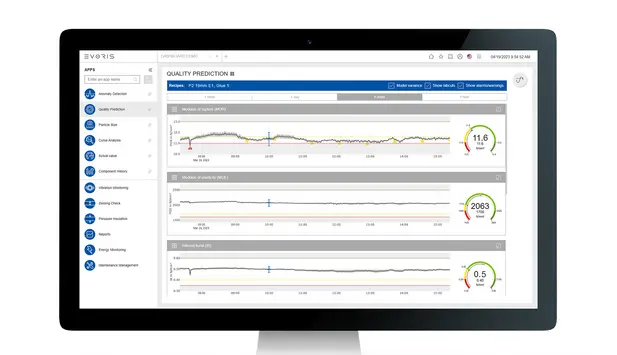

Quality Prediction

Quality Prediction

The self-learning Quality Prediction app is an artificial intelligence-based app. It continuously predicts board quality parameters during panel production. If production parameters change, you see how they affect board quality. When quality deviations are predicted, you can initiate countermeasures quickly to bring board quality back into balance. With prediction accuracies of over 95% for parameters such as internal bond, bending strength, modulus of elasticity, and surface soundness, you can reduce tolerances, increase production speed and systematically optimize board quality. At the same time you avoid rejects and downtime. You also benefit from better documentation of product quality.

BENEFITS

- Reduce plant downtime

- Increase production speed

- Save wood, glue and other resources

- Reach ideal board quality faster

- Reduce tolerances and produce closer to quality limits

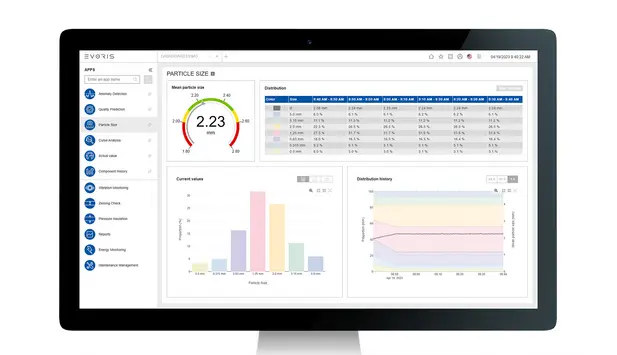

Particle Size

Particle Size

Particle size has a huge impact on board quality and can indicate machine defects or wear, e.g., in the flaking process. Especially high amounts of fine material or too coarse particles can negatively influence product quality. The Particle Size app is similar to a continuous “in-line sieve analysis.” It monitors and visualizes particle size and distribution in real time. This allows you to detect deviations from the desired particle sizes and their distribution and quickly initiate countermeasures to ensure stable board quality. If data from the Particle Size app flows into the Quality Prediction app, you’re even better able to achieve optimum board quality and avoid rejects.

BENEFITS

- Increase your plant availability

- Reduce rejects

- Optimize board quality

- Save raw materials and energy

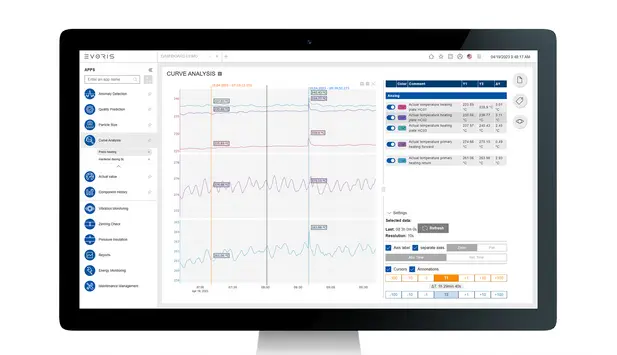

Curve Analysis

Curve Analysis

The Curve Analysis app is a data analysis tool. It visualizes all plant-wide measurement data in curve progressions. You can evaluate live and historic data on any device and easily recognize complex correlations in the production process. This allows you to identify errors comprehensively and to fix them quickly and accurately. At the same time, the app allows you to analyze errors retrospectively to better prevent future machine downtime. The “view storage” function allows you to store and retrieve your view configurations. It facilitates communication between maintenance and service personnel or process managers and machine operators.

BENEFITS

- Prevent plant and machine downtime

- Identify and fix errors quickly and accurately

- Prevent repeated errors

- Facilitate communication around analytics

- Conduct diagnosis flexibly anywhere within the plant via mobile devices

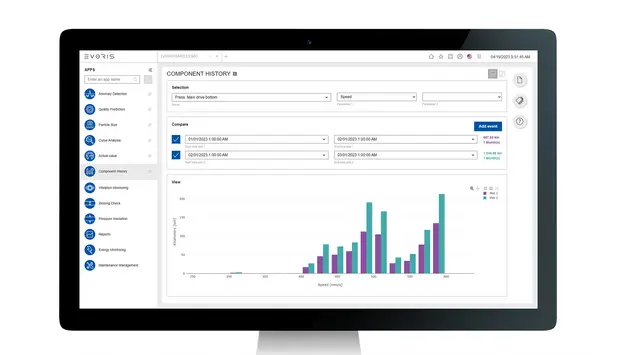

Component History

Component History

The Component History app gives you an overview of the total load borne by plant components, in the form of a load spectrum. The app records the load of components over the entire life cycle and lets you compare load spectra between old and replacement parts, between maintenance steps or specific time periods. The app can also help you find correlations between load and machine parameters. This makes it easier for you to judge the expected lifetime of a part, plan maintenance measures and reduce unplanned downtime.

BENEFITS

- Prevent plant and machine downtime

- Save resources

- Plan maintenance measures more easily and proactively

- Measure and predict the lifetime of machine parts more accurately

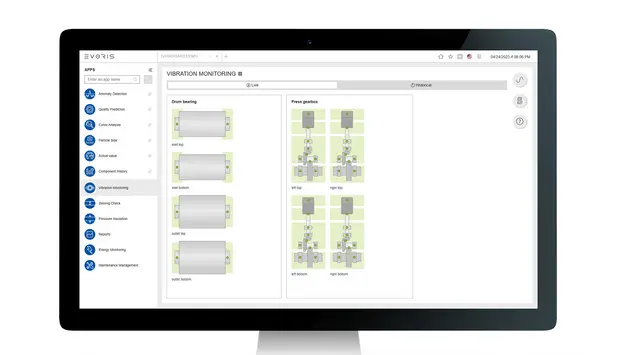

Vibration Monitoring

Vibration Monitoring

The Vibration Monitoring app allows you to continuously monitor vibrations of critical components of your prepress and CPS(+) continuous press like drum bearings, gears and other components. Vibration strength is measured according to machine speed, allowing frequency-specific detection of bearing and gear damage, misalignment and imbalance. Alarms alert you if automatically taught-in limits are exceeded. This helps you identify and eliminate defects and possible wear at an early stage. You can also compare live values with historical views and trends. This supports you in planning preventive maintenance measures.

BENEFITS

- Detect defects and eliminate misalignment at an early stage

- Reduce and shorten unplanned plant and machine downtime

- Plan maintenance measures easily and proactively

- Prevent costly damage to machines

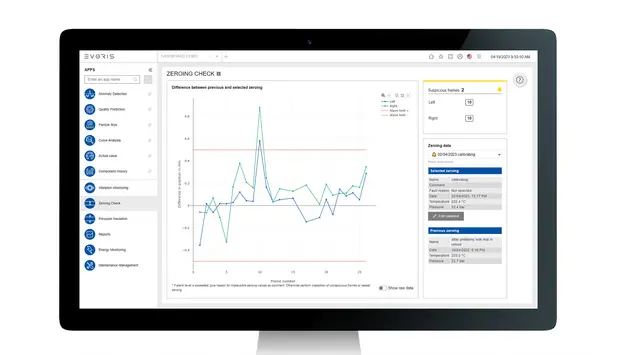

Zeroing Check

Zeroing Check

The Zeroing Check app compares calibration process data for your CPS+ continuous press and recognizes deviations from normal behavior. The app identifies and notifies you of suspicious press frames. Automatic corrections of deviations due to pressure and temperature differences help you avoid misinterpretations. Your operators can detect errors faster and plan maintenance measures proactively. This helps you maintain a stable production quality. By adding comments to data records you avoid repetitive errors.

BENEFITS

- Detect defects and changes faster

- Plan maintenance measures earlier

- Prevent quality degradation and rejects

- Avoid repetitive errors

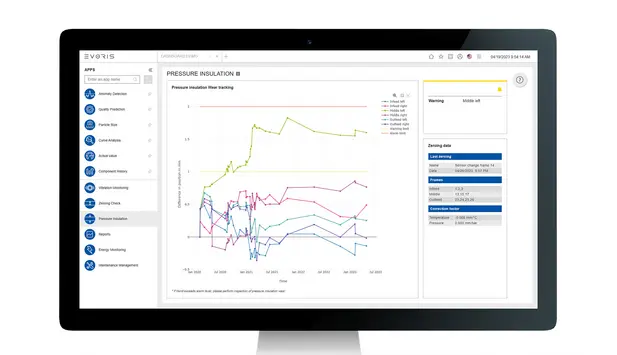

Pressure Insulation

Pressure Insulation

The Pressure Insulation app monitors the insulation thickness of your CPS+ continuous press by evaluating the calibration process data. A reduction of thickness is an indication of wear. The app notifies you if threshold values are exceeded. The calculation of thickness change includes correction of deviations due to pressure, temperature and plausibility which helps you to avoid misinterpretations. This supports your operators in planning maintenance measures early to prevent reduced product quality, rejects and unplanned downtime.

BENEFITS

- Detect defects and changes quickly

- Plan maintenance measures better

- Prevent quality degradation and rejects

- Avoid repetitive errors

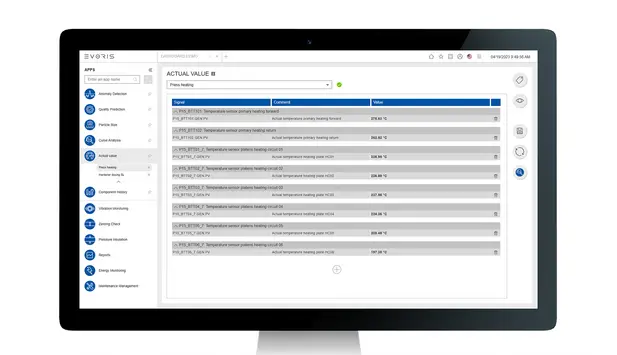

Actual Value

Actual Value

With the Actual Value app you can view and analyze your machine and process values live and anywhere within the plant, e.g. in the control room, or with a mobile device, during maintenance at the machine. You can easily search, select and combine plant-wide data via a user-friendly tag picker or simply scan nameplates of machines to view current process parameters. Selected values can be saved in tables for quick access later. See how parameters change directly as you carry out repair on a machine. This allows you to find errors faster, carry out maintenance more efficiently and track a process as you walk around your plant.

BENEFITS

- View machine and process values quickly and flexibly

- Save time of maintenance tasks

- Get insights into machine parameters directly from the shop floor

- Decide which parameters to view when tracking a production process

- Conduct diagnosis anywhere within the plant via mobile devices

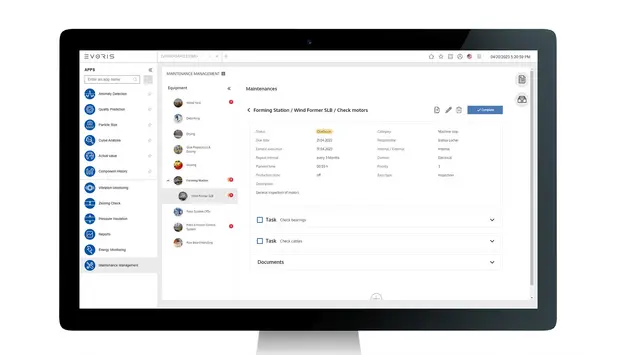

Maintenance Management

Maintenance Management

With the Maintenance Management app you can easily plan, manage and conduct maintenance tasks. The app provides you with a concise and filterable overview of all maintenance tasks for your plant while informing you of the current condition of machines. You can easily see completed or pending jobs. In addition to time-based triggers for maintenance tasks, you benefit from value-based triggers based on the actual load of your machines. The values are measured in other EVORIS apps and communicated to the Maintenance Management app. These comprehensive triggers help you plan more efficiently and save costs. The potential to store information on maintenance tasks like documentation, guides, tools or images supports your personnel during maintenance.

BENEFITS

- Manage maintenance more efficiently

- Benefit from condition-based maintenance triggers

- Plan maintenance proactively

- Reduce plant and machine downtime

- Avoid unnecessary replacements and save costs

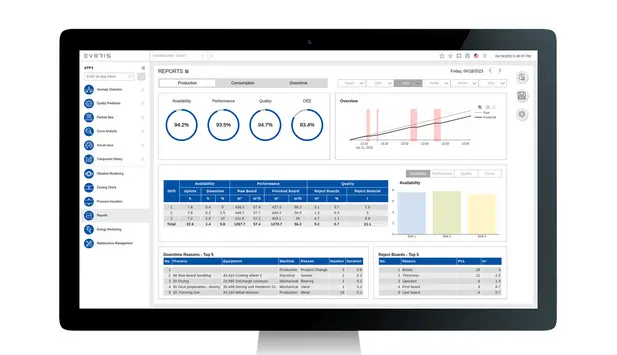

Reports

Reports

Based on your production recipes, Reports monitors your plant production and processes. Production reports for batches and different time periods, laboratory reports with material flow tracking, board data tracking as well as downtime and plant availability reports can be viewed in live streams or exported according to your needs. The use of preconfigured reporting templates and a Manufacturing Execution System (MES) interface allow you to get a quick and comprehensive overview of your production performance. This helps you and your team make better decisions and simplify production planning.

BENEFITS

- Make better decisions faster

- More easily analyze and manage downtime

- Optimize board quality

- Reduce plant and machine downtime

- Improve production performance

Energy Monitoring

Energy Monitoring

The Energy Monitoring app will monitor your thermal and electrical energy consumption, plant-wide and per consumer. This will allow you to compare and evaluate time and place of e.g., unexpectedly high energy consumption values and to identify critical consumers. Your operators will be able to more easily optimize machines and production processes to save energy. You’ll be provided with a reporting of energy consumption by shift, recipe and product as well as energy management data to help you comply with ISO50001.

BENEFITS

- Identify energy-saving potential faster

- Save energy and reduce costs

- Better document improvements concerning energy-saving measures

- Achieve systematic energy management (ISO50001)

EVORIS Services & Support

Get the most from your investment

That's why we offer you comprehensive support: from planning and implementation to the daily use of EVORIS. Your team will receive comprehensive training and support from our EVORIS expert group. With regular software maintenance, updates and further developments of EVORIS, we keep your digital platform up to date.

+ Successfully master plant digitization

+ Build up full EVORIS know-how

+ Receive regular functional and security updates

+ Benefit from app updates and new app development

EVORIS References and Use Cases

Get insights into how EVORIS helps our customers better digitalize and operate of their wood-based panel plant

Explore how EVORIS helps our customers digitalize their plant easily and efficiently to reduce costs and save ressources. In the reference video, the Swiss Krono Group describes how EVORIS helped them digitalize and optimize their wood-based panel plant to achieve higher productivity and avoid downtime.

Here you'll find our EVORIS references and a reference video →

EVORIS – Award winning digitalization and AI solution

For our digital platform EVORIS and the integrated, in-house developed AI, we were honored with the "Allianz Industrie 4.0 Award 2023 Baden-Württemberg" award and as "AI Champion Baden-Württemberg 2024". Here you can find the video about the AI Champion award. Source: Ministry of Economic Affairs, Labor and Tourism Baden-Württemberg.