Get better insights for better decisions:

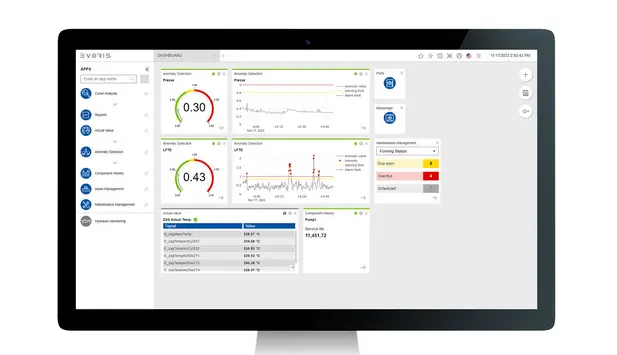

EVORIS enables full machine and process connectivity as well as comprehensive monitoring across the entire plant. This allows you to see complex correlations in the production process that are normally not visible. The software works on smart data processing supported by artificial intelligence. Intuitive EVORIS apps such as Curve Analysis, Anomaly Detection and Reports help you to better understand your forming plant and make your day-to-day business easier.

Benefit from comprehensive support from an experienced partner:

From the very beginning, our EVORIS experts will provide you with comprehensive support and make the digitalization of your production as easy as possible. Your team will receive extensive training and full access to our EVORIS services and support group for quick help with EVORIS solutions. Combining AI and market expertise, our team of experts works closely with you and continuously develops the EVORIS platform.

Your benefits with EVORIS

EVORIS Apps for forming technology

Evoris Platform

EVORIS Platform

The EVORIS platform consists of the iba system, our partner for data acquisition, and the modular, browser-based EVORIS Start Center for your apps. In the iba system, all plant data is collected and processed centrally. All of this information goes into the corresponding apps so that you can gain deep insights into your plant on the intuitive interface of the Start Center. Iba also enables the integration of cameras and camera-based monitoring. Combined with EVORIS Start Center, this is a solution for total connectivity and transparency. Secure access is possible from any mobile or desktop device within a plant's network.

BENEFITS

- Operate the EVORIS solutions easily and intuitively on our browser-based user interface

- Digitalize your production comprehensively and efficiently

- Use a manufacturer-independent system

- Maintain maximum operational reliability and performance through continuous updates

- Collect and process data at a central point

- Access the data system-wide from any mobile or stationary end device

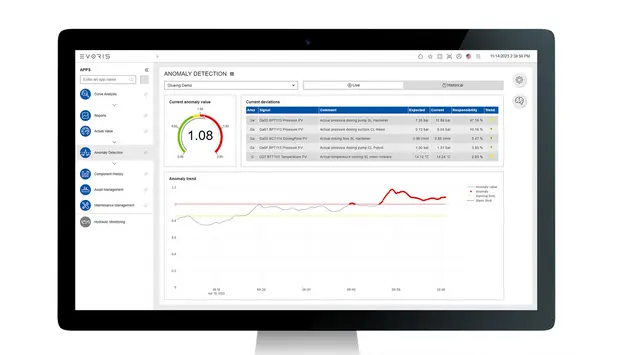

Anomaly Detection

Anomaly Detection

With the self-learning Anomaly Detection app you see exactly when and where deviations occur in your production process. Artificial intelligence is used to permanently monitor and detect deviations from the standard at an early stage. Once learned, the app informs of any deviation from expected production conditions in the current situation and gives you insights into signals causing the anomaly. Operating multiple anomaly models simultaneously allows you to quickly conduct very specific root cause analysis and to proactively intervene, if necessary. This means immense relief for the plant operator: instead of keeping an eye on hundreds of individual values, the Anomaly Detection app only monitors a single anomaly score. If this score is too high, the app displays the causing signals. React in an early stage and address any problem in your forming plant in a targeted manner.

BENEFITS

- Detect deviations, errors and wear at an early stage before they have an impact on your production

- Solve potential problems proactively

- Optimize the planning of preventive maintenance measures

- Reduce downtime, avoid abrupt production stops and increase the productivity of your plant

Curve Analysis

Curve Analysis

The Curve Analysis app is a data analysis tool. It visualizes all plant-wide measurement data in curve progressions. You can evaluate live and historic data on any device and easily recognize complex correlations in the production process. This allows you to identify errors comprehensively and to fix them quickly and accurately. At the same time, the app allows you to analyze errors retrospectively to better prevent future machine downtime. The “view storage” function allows you to store and retrieve your view configurations. It facilitates communication between maintenance and service personnel or process managers and machine operators.

BENEFITS

- Prevent plant and machine downtime

- Identify and fix errors quickly and accurately

- Prevent repeated errors

- Facilitate communication around analytics

- Conduct diagnosis flexibly anywhere within the plant via mobile devices

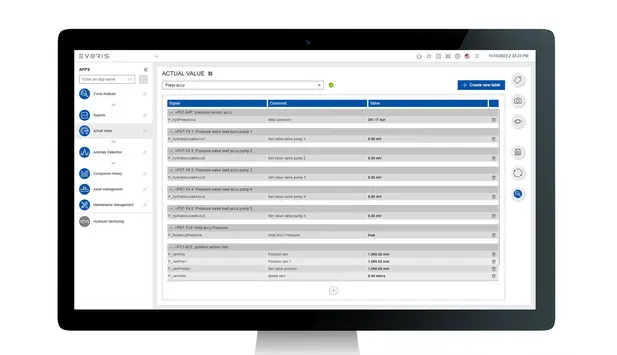

Actual Value

Actual Value

With the Actual Value app you can view and analyze your machine and process values live and anywhere within the plant, e.g. at the control panel, or with a mobile device, during maintenance at the machine. Quickly and easily scan the nameplates on the machines to view current process parameters or use the user-friendly tag picker to search, select and combine plant-wide data. Selected values can be saved in tables for quick access later. See how parameters change directly as you carry out repair on a machine. This allows you to find errors faster, carry out maintenance more efficiently and track a process as you walk around your plant.

BENEFITS

- Access machine and process data quickly and flexibly exactly where you need them

- Save time for maintenance tasks

- Get insights into machine parameters directly from the shop floor

- Decide which parameters to view when tracking a production process

- Conduct diagnosis anywhere within the plant via mobile devices

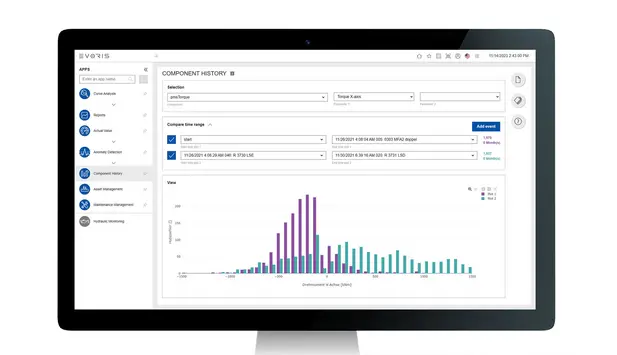

Component History

Component History

Collect valuable data about the total load of machine components with the Component History app. The app records the load of components over the entire life cycle. Compare load spectra between old and replacement parts, between maintenance steps or specific time periods. The app can also help you find correlations between load and machine parameters. This data makes it easier for you to judge the expected lifetime of a component. Maintenance measures become easier for you to plan and unplanned downtimes can be reduced.

BENEFITS

- Get a better overview of the load on a component over its entire life cycle and predict the lifetime of machine parts more accurately

- Derive preventive maintenance measures and energy saving potential easily and proactively

- Prevent plant and machine downtime

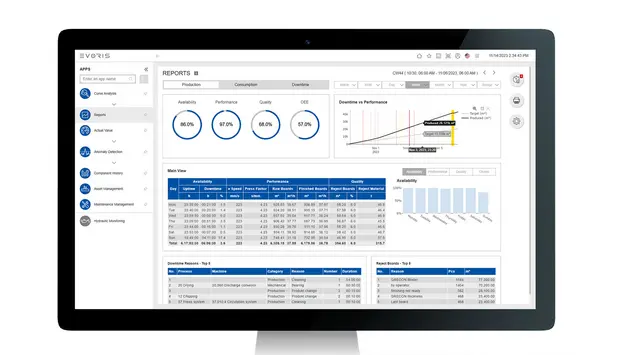

Reports

Reports

The Reports app monitors the parts produced in relation to production batches and time periods, determines consumption data for raw materials and energy and uses this to create production reports. In addition, you can display downtime and plant availability reports together with the cause of the downtime in live streams or export them according to your needs. The application makes it easier for you to allocate data and gives you full transparency of your production and components. The use of preconfigured reporting templates and an ERP/MES interface allow you to get a quick and comprehensive overview of your production performance including the individual PDE data broken down to individual components.

BENEFITS

- Make faster and better decisions

- Improve plant availability

- Minimize plant and machine downtimes

- More easily analyze and manage downtime

- Improve production performance

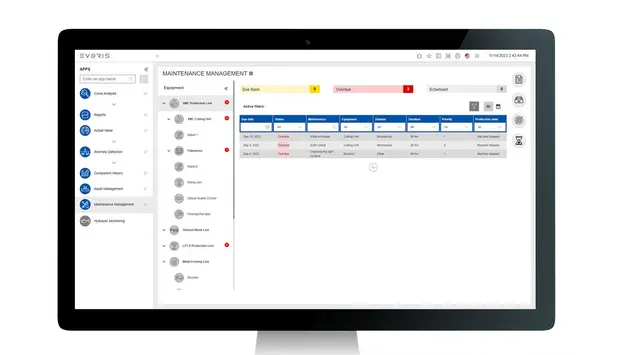

Maintenance Management

Maintenance Management

With the Maintenance Management app you can easily plan, manage and conduct maintenance tasks. The app provides you with a concise and filterable overview of all maintenance tasks for your forming plant while informing you of the current condition of machines. You can easily see completed or pending jobs. In addition to time-based triggers for maintenance tasks, you benefit from value-based triggers based on the actual load of your machines. The values are measured and evaluated in other EVORIS apps, and forwarded to the Maintenance Management app. These comprehensive triggers help you plan more efficiently and save costs. The potential to store information on maintenance tasks like documentation, guides, tools or images simplifies the daily work of your personnel. You can also use the downtime assistant within the Maintenance Management app to plan all necessary maintenance on an ad hoc and long-term basis at the specified downtimes.

BENEFITS

- Manage maintenance more efficiently

- Benefit from condition-based maintenance triggers

- Plan maintenance proactively

- Reduce plant and machine downtime

- Avoid unnecessary replacements and save costs

Hydraulic Monitoring

Hydraulic Monitoring

Hydraulic Monitoring is a plant-wide monitoring, based on anomaly detection, which can increase your preventive maintenance measures to the max. Only the necessary maintenance measures are implemented and defects are detected at an early stage before they can have an impact on the overall system. An oil change is an example that clearly shows the benefits: The oil change is a costly part of hydraulic press maintenance. In the past, oil changes were recommended after a certain period of time. With the Hydraulic Monitoring app, all relevant influences on the aging of the oil and their occurrence will be known. Hydaulic monitoring gives the maintenance engineer a data-based assessment of the current condition, an estimate of the remaining service life and makes maintenance plannable.

BENEFITS

- AI-based monitoring of the overall hydraulic system

- Plannable maintenance

- Maximum machine availability through early detection of deviations from the standard condition of the hydraulic system

Energy Monitoring

Energy Monitoring (coming soon)

The Energy Monitoring app monitors your energy consumption, plant-wide and per consumer. This will allow you to compare and evaluate time and place of e.g., unexpectedly high energy consumption values and to identify critical consumers. Your operators will be able to more easily optimize machines and production processes to save energy. You’ll be provided with a reporting of energy consumption by shift, recipe and product as well as energy management data to help you comply with ISO50001.

BENEFITS

- Identify energy-saving potential faster

- Save energy and reduce costs

- Document improvements in energy-saving measures more easily

- Achieve systematic energy management (ISO50001)

EVORIS for Forming: Services & Support

We support you every step of the way in digitizing your plant

Our aim is to provide you with the best possible support in unlocking the full potential of your system through digitalization. We support you from planning and implementation to the daily use of EVORIS. Your team will not only receive intensive training, but also continuous support from our EVORIS experts. With regular software maintenance, updates and further developments of EVORIS, we keep your digital platform always up to dat

- Successfully digitize your forming plant

- Develop full EVORIS expertise

- Receive regular functional and security updates

- Benefit from continuous app updates and new app development

EVORIS at our customer Autoneum in Switzerland

How EVORIS makes the production of automotive components at Autoneum more efficient

Awards for our AI-based digitalization platform EVORIS

Our AI-based digitalization solution EVORIS was honored with two awards: “Allianz Industrie 4.0 Award 2023 Baden-Württemberg” and “KI-Champion Baden-Württemberg 2024”. Find out more about the AI Champion Baden-Württemberg 2024 award in the video. Source: Ministry of Economic Affairs, Labor and Tourism Baden-Württemberg.