More economical processes with CEBRO

Discover our solutions to improve operational excellence in the forming industry:

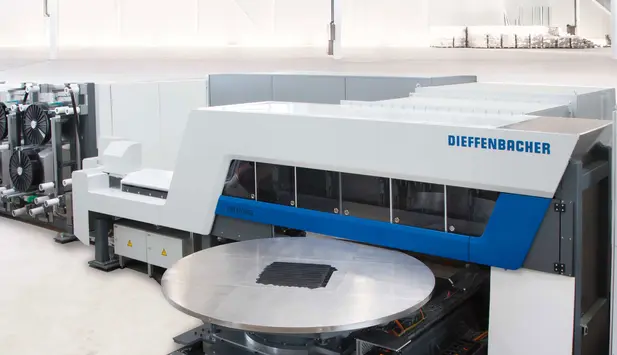

SMC Fibercut

SMC Fibercut

The Dieffenbacher Fibercut improves your plant availability when processing SMC material while also boosting production quality with minimal material consumption.

- Combined longitudinal and cross sections to create complex layouts

- Intelligent nesting control to automatically determine the optimal cut and reduce the amount of material used

- Automatic weight compensation

- Innovative quick-change system reduces the SMC coil or SMC festoon changeover time to less than 5 minutes (OEE improvements of up to 6% possible)

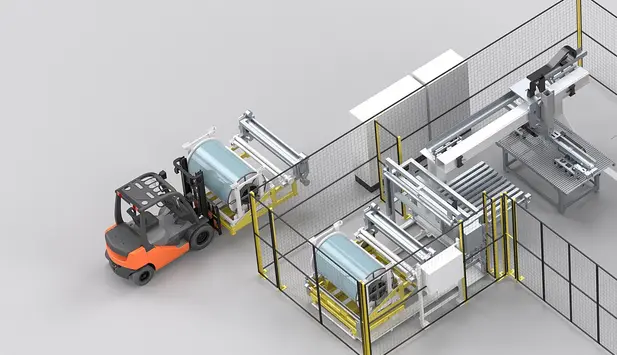

Fiberforge tape laying system

Fiberforge tape laying system

The Dieffenbacher Fiberforge is the fastest tape laying system in the world, making the processing of thermoplastics – even for large series – faster and more efficient. Your components achieve excellent material properties.

- Faster tape laying speed of up to one second per tape

- Higher material throughput, up to 490 kg/h

- Accurate placement of multiple layers in repeatable and reliable positioning

- Near-net-shape laying due to integrated angle cut and combination of different tape widths

Fibercon consolidation system

Fibercon consolidation system

The Dieffenbacher Fibercon consolidates tape fabrics into near-net-shape laminates. By applying a vacuum, you can obtain high-quality components with exceptionally good material properties despite very short cycle times.

- Shorter cycle times as a result of simultaneous processing of multiple fabrics

- Flexibility in the contour of the scrim

- Adaptable to the polymer to be processed (suitable for processing PP, PA6.6, PEEK, PAEK, etc.)

LFT-D compounding line

LFT-D compounding line

Dieffenbacher’s two-extruder technology enables more efficient and flexible LFT component production.

- More efficient and flexible LFT production with demand-oriented extruder pairs

- Reduced material usage and improved component quality due to homogeneous fiber division due to pre-contouring of the LFT-D strands using the servo nozzle

- Material-friendly, sustainable and efficient due to the use of recycled polymers and natural fibers

- Reduction of semi-finished product consumption due to individual adjustment of the material recipe directly during the ongoing production process

- Adjustment of fiber content, tailored to your component

Service

for maximum machine availability

Service for maximum machine availability

After the commissioning of our machines and plants, we are by your side as a reliable partner. Benefit from:

- Key account service with regular meetings on site

- Service contract with extended availability

- Modern online tools such as messenger, 24-hour service/fault rectification and spare parts catalog for fast support

Advantages with CEBRO on the path to improving Operational Excellence:

Save costs through reduced time and material usage

Improve component quality through maximum precision in production

Gain more flexibility in the production process thanks to customization options tailored to your needs

Increase output through efficient production processes

Benefit from long-lasting machines maintained by comprehensive services