Anomaly Detection

The EVORIS Anomaly Detection app leads to higher plant availability and productivity.

Anomaly Detection is a browser-based app supported by artificial intelligence that allows you to detect deviations from the normal state of a production. In case of deviations, you can react quickly, prevent errors before they occur and increase your plant availability and productivity.

Your benefits with Anomaly Detection

Anomaly Detection Impressions

Explore the Anomaly Detection app features

AI-based anomaly detection

Anomaly detection takes advantage of artificial intelligence and machine learning. Developed together with the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB, our technology automatically recognizes target values for relevant production parameters after a short learning phase. Anomaly detection measures and calculates deviations from normal production.

Live data on anomalies

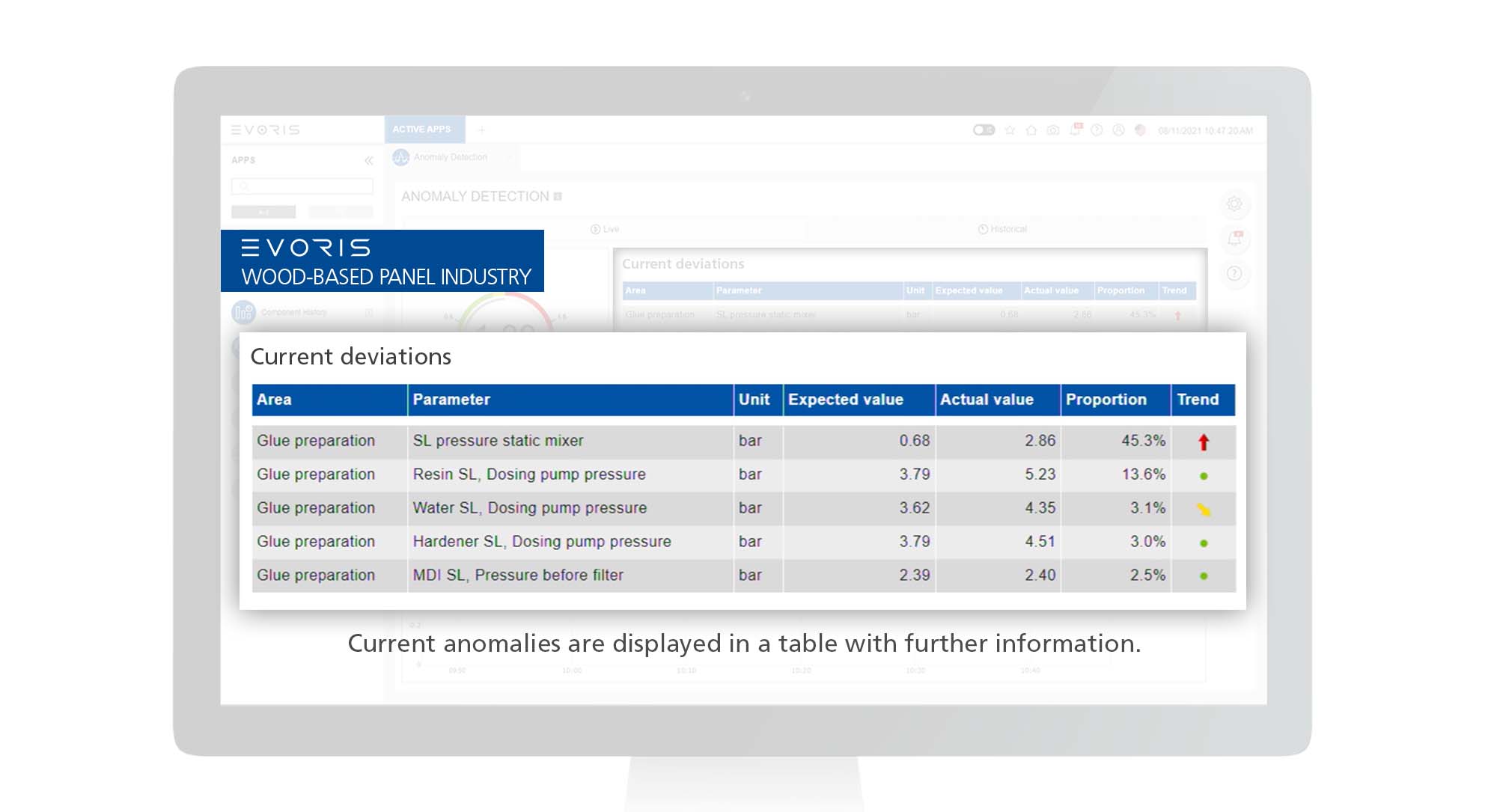

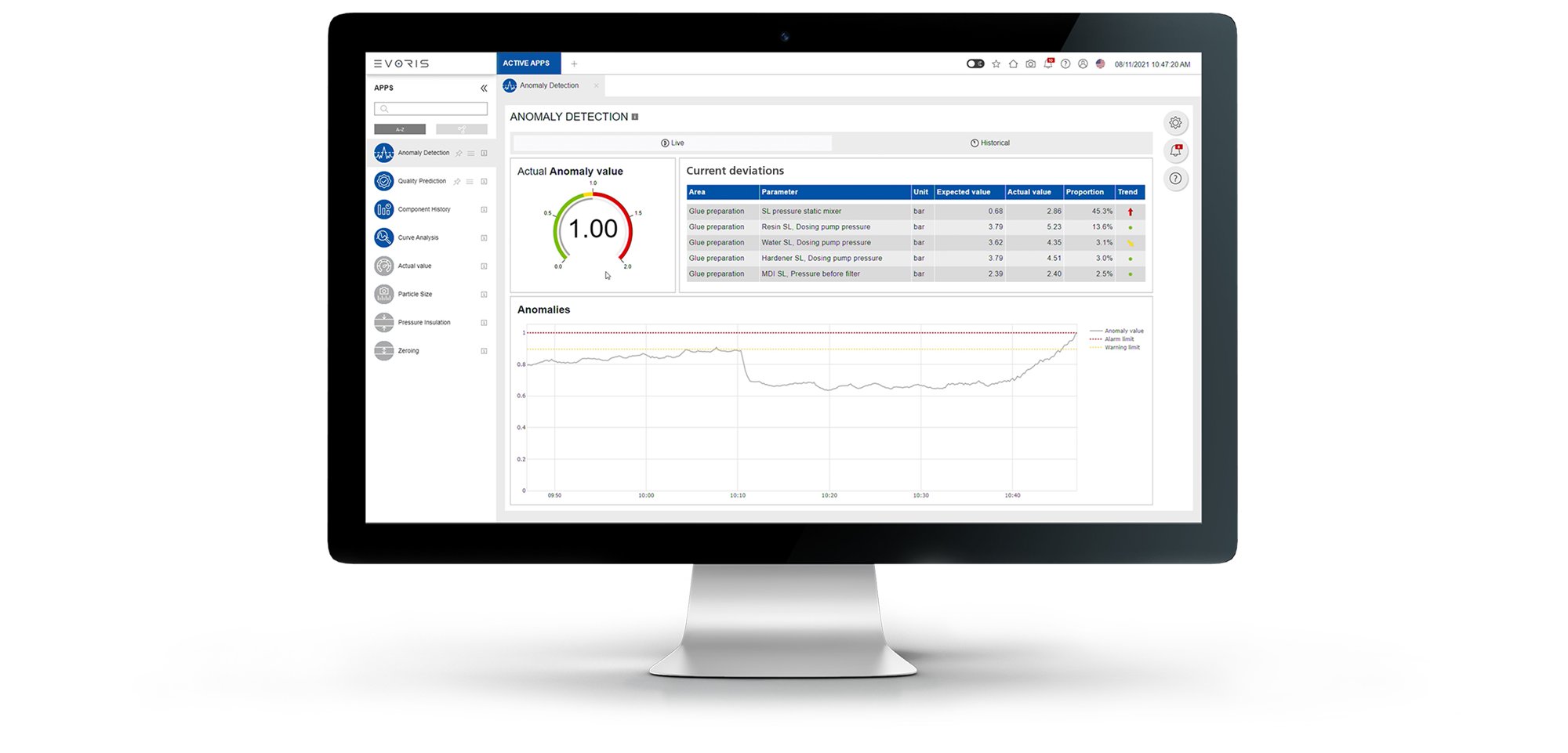

The Anomaly Detection app constantly monitors production-relevant parameters and calculates deviations. For wood-based material manufacturers, these parameters include pressures, temperatures, glue quantity, production speed or moisture, and for forming customers, factors such as press forces, component temperatures, pressures, cycle and handling time. Deviations from the normal state of production become directly visible. As a result, plant operators can quickly detect a parameter violation at an early stage. With this information, they can check the anomaly quickly and accurately and initiate error corrections to prevent production downtimes or shorten them.

Performance monitoring of components and machines

In addition to quality-relevant production parameters, your machines and components can also be included in anomaly detection in order to monitor their performance.

Historical anomaly data

In addition to live data, you can also view historical anomalies. Production history becomes more transparent and can be analyzed retrospectively. This facilitates, for example, shift handovers and the detection of reoccurring errors.

Modern user interface

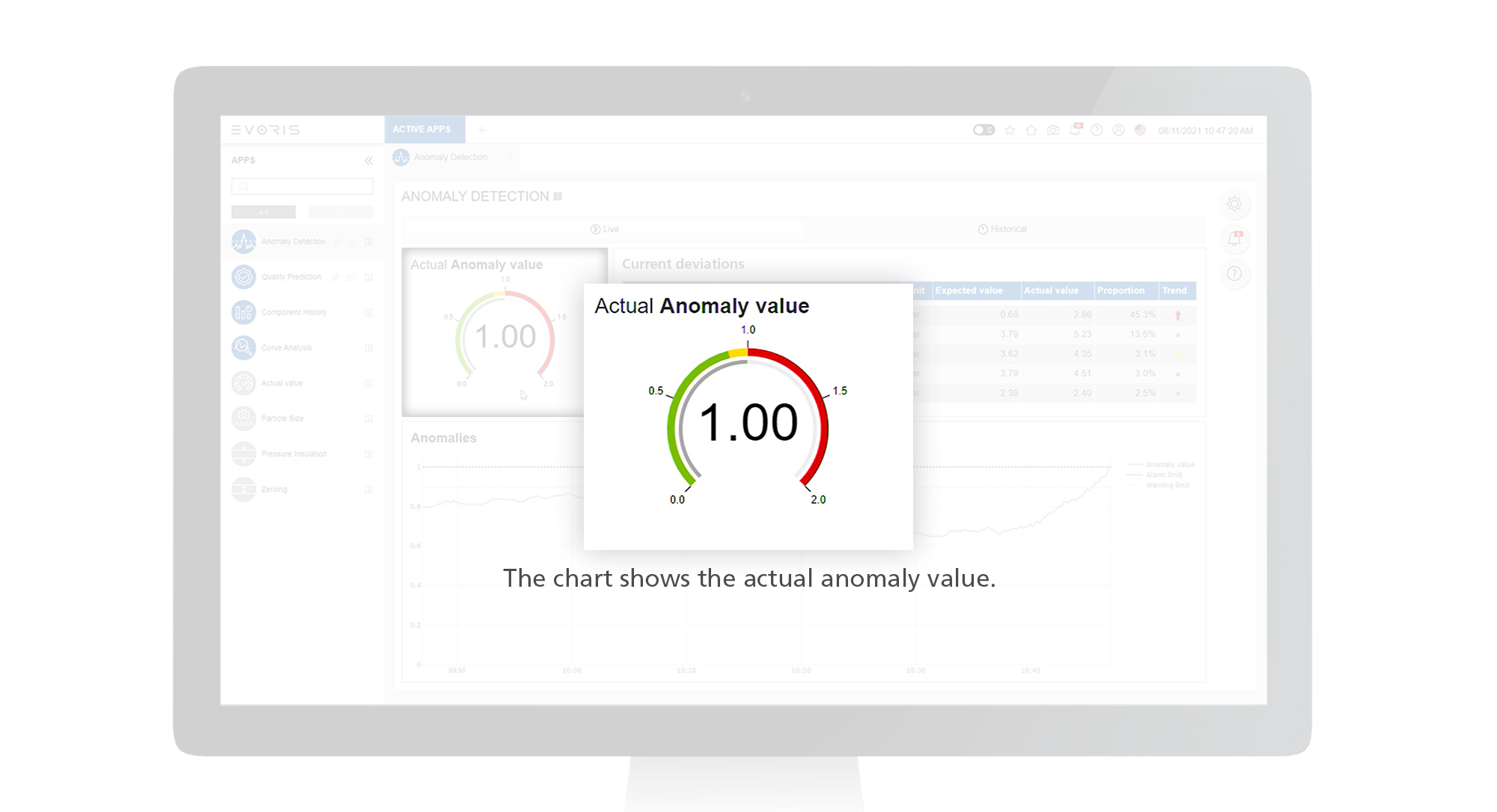

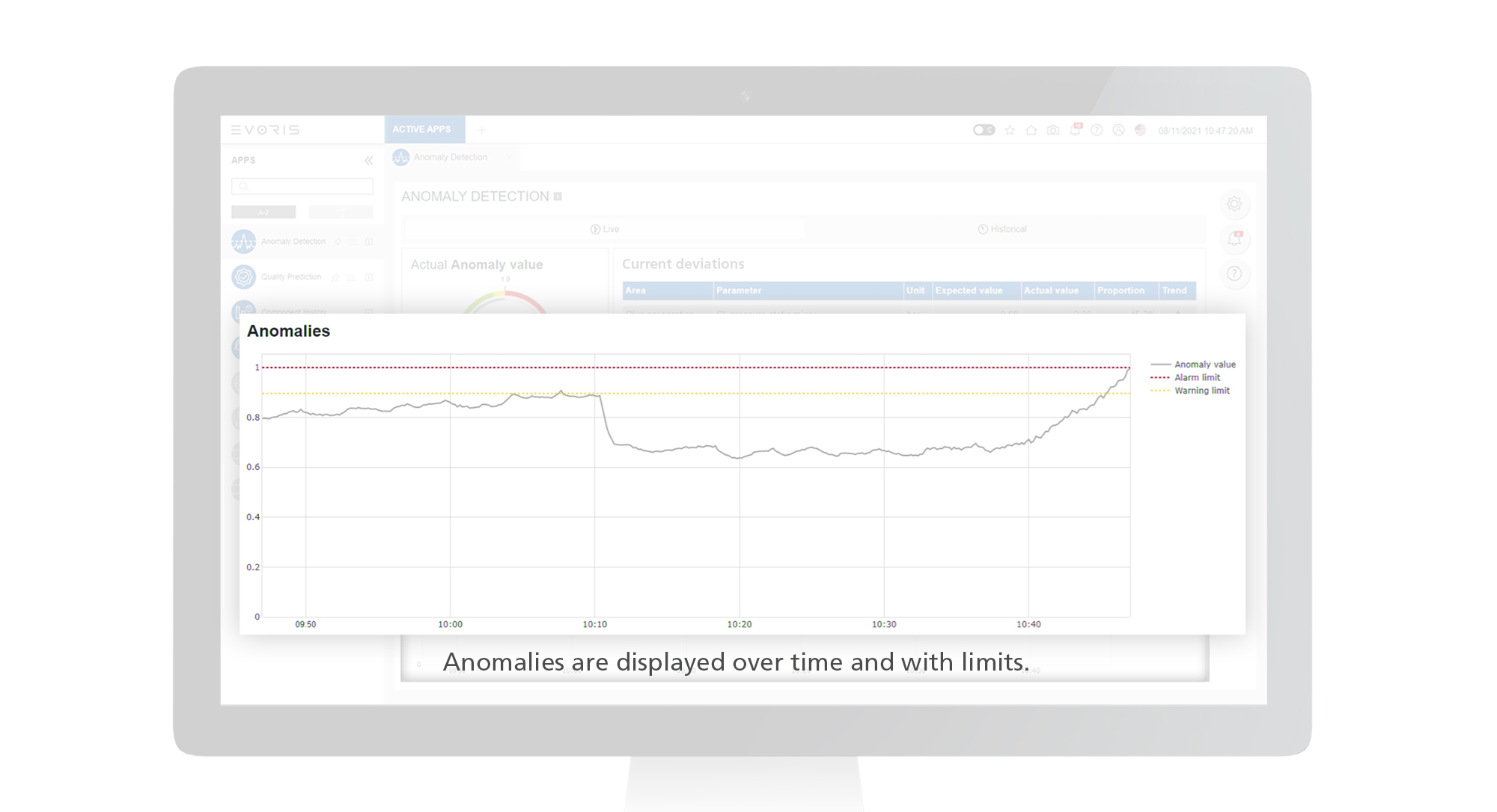

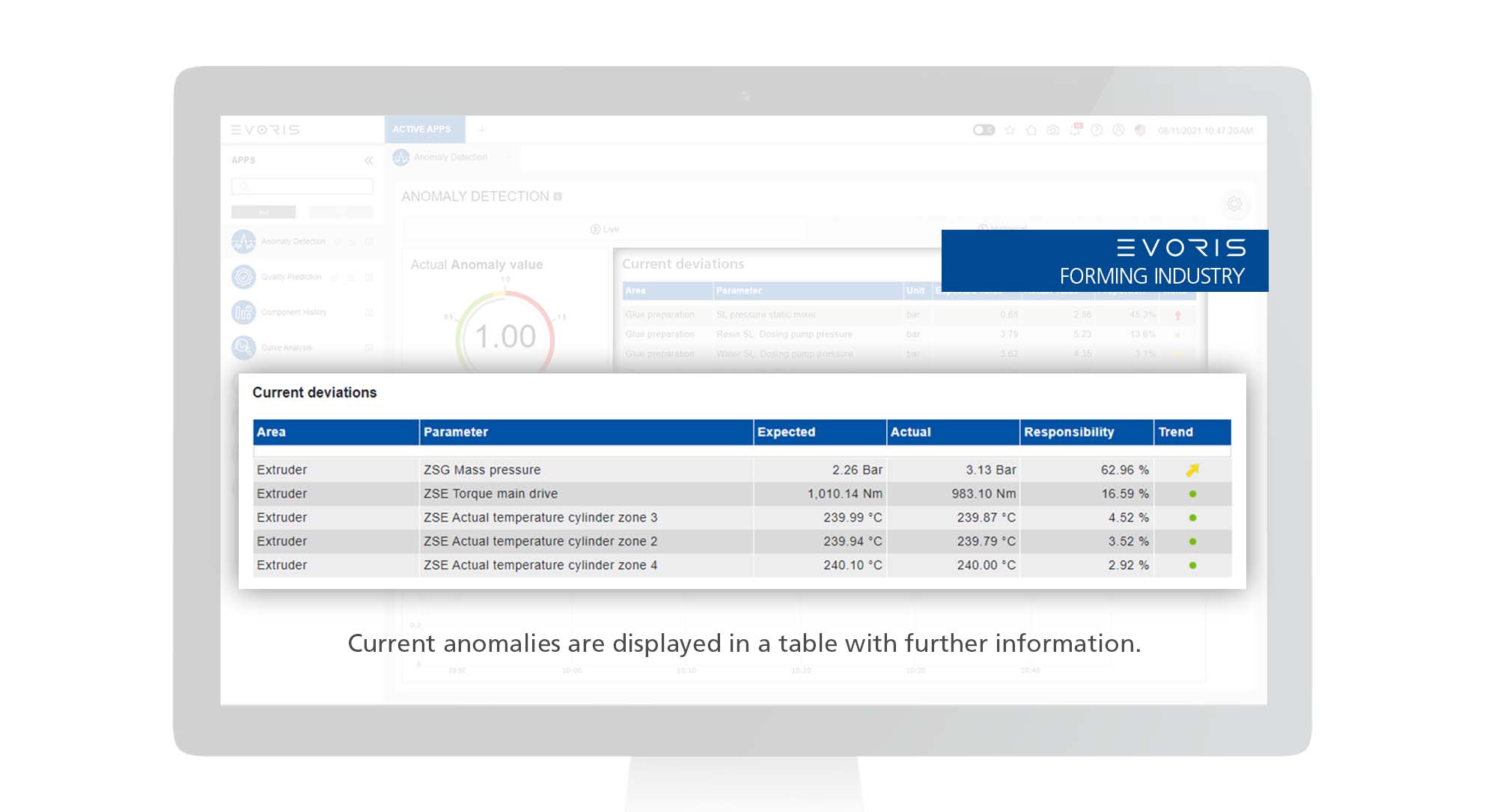

Via the app’s intuitive user interface, you’ll quickly see when limit values are exceeded or undershot. To identify the originators of anomalies, you can view detailed information on each anomaly. An overview displays the most striking deviations to help you prioritize potential issues.

Live view of anomalies

The live view of the anomaly curve shows current deviations from the normal state of production. Deviations can be quickly detected, and early countermeasures for higher plant availability are possible.

Anomaly history

The anomaly history shows historical anomalies and anomaly originators, enabling analysis.

How Anomaly Detection helps you achieve smart production

Improves quality

Reduces downtime

Reduces rejects

Saves resources

Your contact

EVORIS for the wood-based panel industry

Stephan Kruse

Modernization Manager

Stephan.Kruse@dieffenbacher.de

+49 7262 65 212

EVORIS for the forming industry

Jonas Schmid

Product Owner EVORIS

jonas.schmid@dieffenbacher.de

+49 7262 65 5721

More ways to help you move forward

Wood-based panels

Find out more

Forming

Find out more